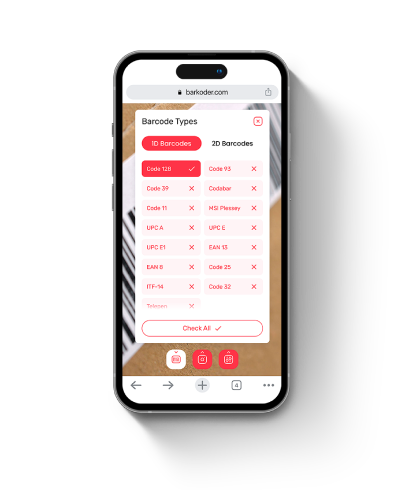

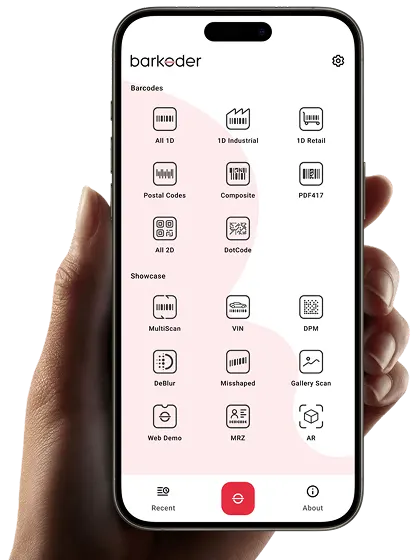

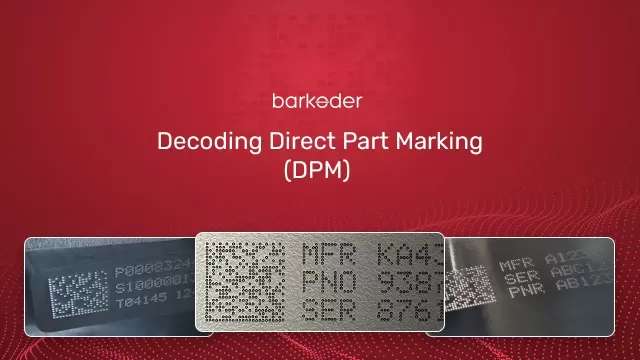

DPM Barcode Scanner SDK

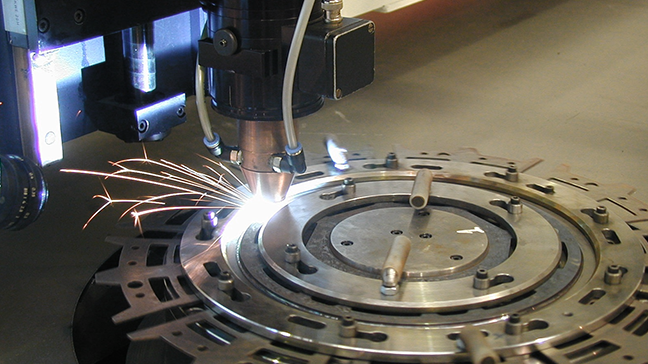

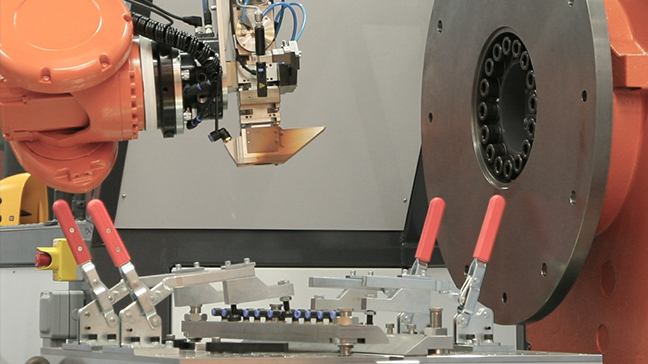

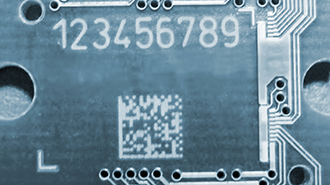

Regardless of the surface, the barKoder Barcode Scanner SDK can accurately read any Data Matrix code engraved via Direct Part Marking (DPM) methods. Traceability, quality control, compliance, and data management via DPM scanning has never been easier.