Warehousing made easy

Efficient warehousing and logistics depend heavily on accurate, timely data, which barcodes deliver reliably. Barcode technology, with its precise identification and tracking capabilities, has become fundamental in managing the vast quantities of products moving through warehouses and logistic centers daily.

Why Barcodes Are Essential in Warehousing and Logistics

Barcodes significantly enhance accuracy, efficiency, and speed in inventory management and logistics. They minimize human error, provide instant access to product information, and streamline operational workflows. By automating data entry, barcodes reduce manual processes, ensuring fewer mistakes, faster inventory counts, and timely product dispatches.

Types of Barcodes Used in Warehousing and Logistics

Warehouses and logistic operations typically use several barcode symbologies, each chosen for specific benefits such as data density, readability, and suitability for various conditions.

Code 128

Code 128 barcodes are extensively used in logistics operations due to their high data-density capability. They encode both numeric and alphanumeric characters, providing flexibility for detailed product information. Companies like FedEx utilize Code 128 because it allows for comprehensive shipment details in a compact space, improving efficiency in scanning and processing parcels rapidly.

Strengths of Code 128

Code 128's primary strength lies in its ability to encode extensive data within a compact barcode, ensuring high readability even in smaller labels. Its error-checking features help maintain data integrity, reducing scanning errors in busy warehouse environments.

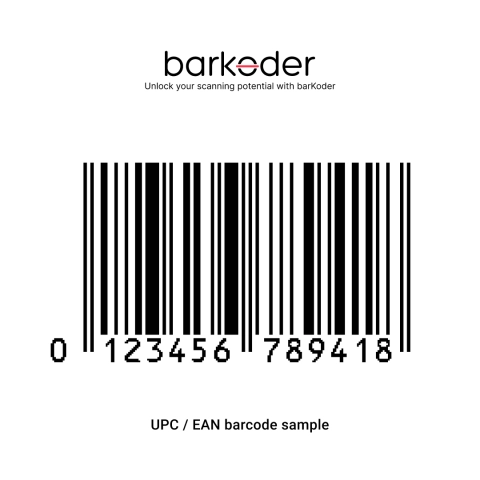

UPC/EAN

Universal Product Code (UPC) and European Article Number (EAN) are widely adopted in retail warehousing operations for inventory management. Retail giants such as Walmart and Target rely on UPC/EAN barcodes to maintain accurate stock levels and manage large-scale inventory seamlessly across distribution centers and retail stores.

Strengths of UPC/EAN

UPC and EAN codes are straightforward, universally accepted, and excellent for fast, high-volume scanning environments. They enhance transaction speed at checkout points and simplify stock replenishment procedures by quickly identifying products with a minimal error rate.

Interleaved 2 of 5

Interleaved 2 of 5 (ITF) barcodes are predominantly used in packaging and shipping cartons within logistics. Major logistics companies such as DHL and UPS commonly apply ITF barcodes on cartons and pallets, enabling rapid bulk scanning during warehouse sorting and distribution processes.

Strengths of Interleaved 2 of 5

The symbology's key advantage is its efficiency in encoding numerical data compactly, making it ideal for cartons and shipping containers where speed and clarity in identification are critical. Its reliable scanning performance even at significant distances ensures smooth workflow operations.

Data Matrix

Data Matrix codes are two-dimensional barcodes frequently used in environments where space is limited but detailed product traceability is crucial, such as pharmaceutical logistics and automotive part tracking. Pfizer, for instance, employs Data Matrix codes extensively for pharmaceutical packaging to ensure accurate traceability from manufacturing to delivery.

Strengths of Data Matrix

The compactness of Data Matrix codes allows storage of substantial information within a minimal physical footprint, providing robust readability even when partially damaged or obscured. They offer high redundancy and error-correction capabilities, essential for maintaining data accuracy in critical sectors.

Real-Life Examples of Barcode Implementation in Warehousing and Logistics

Amazon's Inventory Management

Amazon, one of the world's largest retailers, extensively employs barcode technology, particularly UPC and Code 128, across its vast network of warehouses. By scanning products at multiple stages—from receipt at the warehouse to storage and eventual dispatch—Amazon ensures accurate inventory counts and efficient product flow, enabling rapid fulfillment for millions of customers daily.

DHL's Efficient Package Handling

DHL integrates Interleaved 2 of 5 barcodes in its operations to quickly process bulk shipments. The application of these barcodes on cartons and pallets allows DHL to swiftly sort, route, and track large volumes of packages, greatly enhancing their efficiency and accuracy across global logistics networks.

Pharmaceutical Traceability at Pfizer

Pfizer uses Data Matrix barcodes on product packages to meet stringent regulatory compliance and enhance product traceability. Each barcode contains detailed information, including batch number, expiry date, and product specifics, ensuring complete visibility throughout the supply chain and significantly reducing medication errors and counterfeit issues.

Conclusion

Barcodes remain an indispensable tool in warehousing and logistics, offering diverse solutions tailored to different operational requirements. Choosing the correct barcode symbology depends on the specific needs of data capacity, environmental resilience, and readability, ultimately optimizing accuracy, efficiency, and speed throughout the supply chain.