Safety & Efficiency on construction sites to the next level

Barcodes are increasingly being adopted across the construction industry as a pivotal technology to substantially enhance efficiency and accuracy in comprehensive material tracking and detailed inventory management systems. These valuable identification markers are strategically applied to a wide range of construction materials, specialized equipment, and essential tools to systematically monitor their movement and status throughout the entire supply chain process.

Here are some key areas where barcodes are transforming construction:

- Material tracking: Barcodes meticulously track construction materials from initial supplier warehouses all the way to the final job site location, enabling comprehensive real-time inventory monitoring and management. This systematic approach effectively prevents costly shortages, eliminates unnecessary overstocking, and significantly reduces material waste across projects. These versatile identification systems can be seamlessly applied to various building materials including dimensional lumber, structural piping, reinforcement steel, prefabricated components, and numerous other essential building materials used throughout construction phases.

- Equipment and tool tracking: Barcodes thoroughly monitor construction equipment and tools throughout their complete lifecycle as they are initially rented, actively used on-site, and eventually returned to storage facilities. This comprehensive tracking system provides exceptionally accurate records of usage patterns and maintenance schedules, substantially improving workplace safety conditions and effectively deterring potential theft incidents. These identification markers can be strategically applied to heavy equipment such as industrial cranes, hydraulic excavators, bulldozers, forklifts, and various power tools essential for daily construction operations.

- Time and attendance tracking: Construction workers can conveniently scan personalized barcodes using standard mobile devices to accurately clock in and out of job sites, providing management with extremely precise data regarding actual hours worked on specific projects and effectively preventing potential time theft issues. This system also enables improved labor allocation and project planning based on comprehensive attendance data.

Common barcode types used in construction include:

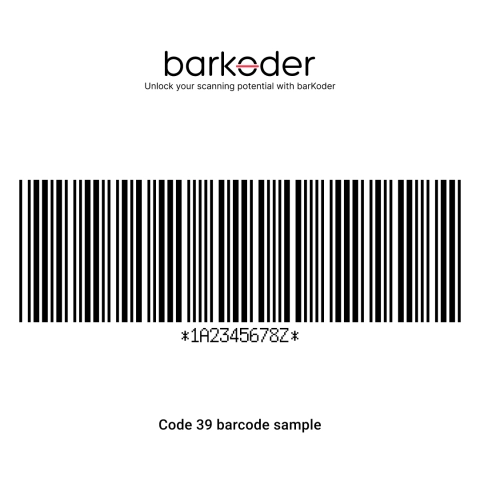

Code 39: A widely implemented and highly reliable barcode type in construction environments that efficiently encodes alphanumeric data sequences, commonly utilized for comprehensive tracking of inventory items and valuable assets throughout construction sites;

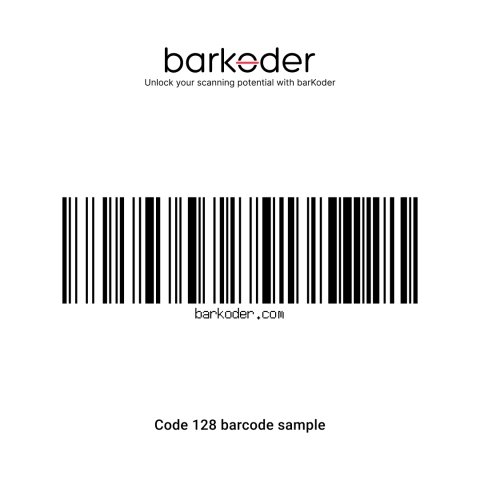

Code 128: A particularly popular and versatile barcode type specifically designed to encode substantially larger amounts of detailed data, frequently implemented for systematic labeling and precise tracking of building materials, equipment inventories, and component deliveries;

QR Code: Rapidly gaining widespread popularity in modern construction operations due to their exceptional ability to store substantial quantities of varied data, including complete URLs, detailed contact information, and comprehensive project specifications. These versatile codes effectively track equipment status, material inventories, and ongoing project progress with remarkable accuracy;

Data Matrix: Functionally similar to QR codes but with distinctive formatting, these compact codes efficiently store large volumes of critical data in remarkably small physical spaces and are increasingly utilized for precise tracking and instant identification of specialized materials and valuable equipment;

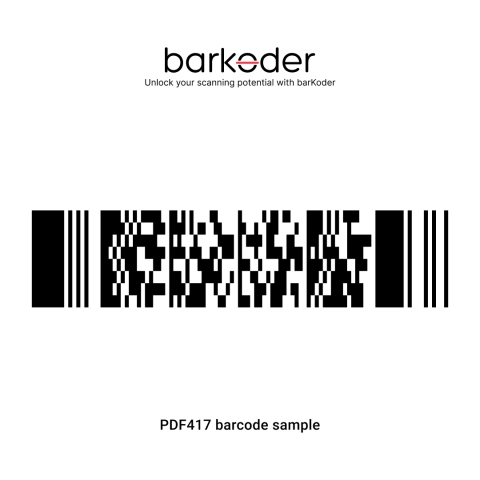

PDF417: A sophisticated two-dimensional barcode system capable of storing extensive amounts of varied data types, including formatted text, numerical sequences, and even embedded images. This advanced format is particularly valuable for comprehensive asset tracking applications and detailed inventory management systems on large-scale construction projects.

These diverse barcode types collectively serve multiple essential functions throughout the construction industry, ranging from meticulous tracking of inventory levels and valuable assets to efficiently managing equipment checkout procedures and providing immediate access to critical project information through standard mobile devices used by on-site personnel.

Barcodes have rapidly evolved to become an absolutely essential technological tool in modern construction operations for significantly boosting operational efficiency, dramatically cutting preventable material waste, and substantially enhancing workplace safety protocols. By implementing systems that accurately track materials throughout their lifecycle, monitor equipment utilization patterns, and verify worker presence, the construction industry can operate with remarkably improved smoothness, consistency, and operational effectiveness.

Mobile barcode decoding technology allows construction workers to instantly scan and accurately interpret various barcode formats using standard smartphones or tablet devices without requiring specialized equipment. Site personnel can efficiently scan barcodes affixed to materials, equipment, or tools to immediately access critical operational information such as current inventory levels, comprehensive maintenance history records, and precise location tracking data throughout the project timeline.

Here's how mobile barcode decoding is specifically used in construction:

- Material tracking: Construction workers systematically scan unique barcodes attached to incoming materials immediately upon their arrival at the active job site, enabling exceptionally precise inventory tracking capabilities and providing instantaneous real-time updates to detailed project schedules and material allocation plans. This comprehensive approach significantly helps prevent costly errors and substantially reduces material waste by ensuring the appropriate materials are correctly identified and utilized for each specific construction task or installation phase.

- Equipment and tool tracking: Mobile scanning technology efficiently tracks valuable equipment and essential tools as they continuously move around dynamic job sites throughout the project duration. By regularly scanning designated barcodes, workers can instantly access comprehensive equipment maintenance history records, current location information, and detailed usage statistics, significantly improving workplace safety conditions and effectively preventing potential theft or misplacement of valuable assets.

- Safety inspections: Specialized barcodes systematically track mandatory safety inspections performed on equipment and tools throughout the construction process. Authorized personnel scan these barcodes to access complete inspection records and verify that all required safety checks are properly documented and currently up-to-date, ensuring full compliance with safety regulations and reducing workplace accident risks.

Mobile barcode decoding implementations typically utilize a specialized scanning application installed on a standard smartphone or tablet device. The purpose-built application effectively utilizes the device's integrated camera to capture and instantly decode the embedded barcode information, which can then be securely stored in a centralized database or transmitted to a dedicated central server for comprehensive real-time tracking analysis and project management integration.

Mobile barcode decoding has proven to be an incredibly valuable technological tool in the modern construction industry for dramatically improving operational efficiency, substantially reducing preventable material waste, and significantly enhancing overall workplace safety standards. By implementing systems that enable construction workers to instantly scan and process barcodes using readily available mobile devices, project managers can ensure their teams access critical operational information immediately when needed, notably improving comprehensive project management capabilities and effectively streamlining daily construction operations throughout all project phases.