Why Old Warehouse Scanners Cost More Than You Think in 2026

For years, warehouse managers held onto one belief:

“These handheld scanners last forever. Why replace something that still works?”

On the surface, it makes perfect sense. The devices look tough. They rarely break. And they’ve been in use for so long that nobody stops to question them anymore.

But here’s the hidden reality most warehouses overlook:

Old handheld scanners are silently draining budgets, slowing down workers, hurting productivity, and sabotaging operational efficiency , every single day.

The real issue isn’t what managers notice… it’s everything they don’t.

The Myth of the “Everlasting Scanner”

Legacy scanners built in the 2000s/early 2010s were designed like bricks: chunky, industrial, and nearly indestructible. And that’s exactly why many warehouses think:

- “We already paid for them.”

- “They still turn on.”

- “They still scan barcodes.”

But durability ≠ efficiency.

In 2026, a device that only scans is outdated. Warehouses now run on speed, software, automation, and real-time visibility.

Old scanners weren’t built for any of that, and today, they’re the slowest piece of your operational chain.

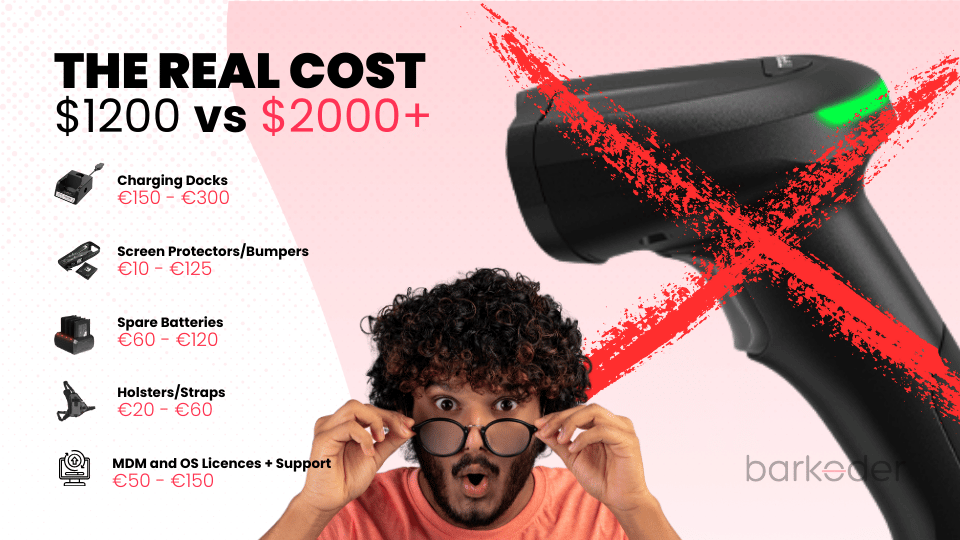

The Real Purchase Cost:

Much Higher Than You Remember

Most managers remember the €1,200 invoice from 5 years ago and think that was the “big expense.”

Not even close.

Here’s the real cost breakdown for a single industrial handheld:

Hardware Device: €900–€1,500

Depending on brand (Zebra, Honeywell, Datalogic), industrial scanners are extremely expensive upfront.

Accessories You Can’t Avoid

Most warehouses forget these:

- Charging docks: €150–€300 each

- Spare batteries: €60–€120

- Holsters/straps: €20–€60

- Screen protectors / bumpers: €10–€25

- Cradles / communication bases: €200–€350

Software Licensing

Many scanners require:

- MDM licenses

- OEM OS licensing

- Paid firmware updates

- Paid support plans

Annual cost per device: €50–€150

Already, the “€1,200 device” becomes a €2,000+ total purchase.

The Invisible Maintenance Sinkhole

Here’s where the real budget burn happens — and most managers never see it clearly.

Repairs: €200–€400 per incident

Screens crack. Buttons wear out. Triggers die.

Even a “simple” repair includes:

- Labor costs

- Part replacement

- Shipping

- Device downtime

Battery Replacements

Old scanners lose battery health fast.

Cost per replacement: €70–€120

Frequency: every 12–18 months

Multiply by dozens of devices, and it’s thousands per year.

Downtime = Lost Money

When a scanner is out for repair:

- Picking slows down

- Workers share devices

- Productivity drops

- Errors increase

Warehouses lose money in minutes, not hours.

Limited Part Availability

Older scanners often:

- Are discontinued

- Have no available replacement parts

- Rely on third-party repairs

- Cannot receive security updates

Meaning: the device “works,” but operational risk increases every day.

Worker Inefficiency: The Most Expensive Hidden Cost

This is where warehouses lose the most money — not in hardware, but in human time.

Slow Scanning Speed

Old scanners decode slowly, especially:

- Damaged barcodes

- Curved barcodes

- Low-contrast labels

- Small Data Matrix codes

Each slow scan = a micro delay.

Micro delays × thousands of scans/day × 50 workers = massive time loss.

Frequent Scan Failures

Workers constantly need to:

- Re-scan

- Adjust distance

- Tilt angles

- Clean lenses

Every extra motion adds fatigue and decreases efficiency.

Heavy & Bulky Designs

Old scanners weigh 3–4× more than smartphones.

Heavier device → slower movement → more exhaustion → more errors.

Fatigue = Accuracy Drops

Warehouse studies show:

Tired workers make 2–5× more picking errors.

And old scanners make workers tired faster.

Technology Limitations That Hurt Modern Operations

Legacy scanners are stuck in the past. They lack:

No AR Picking or Visual Guidance

Workers can't:

- See arrows

- Get on-screen instructions

- See overlays

- Follow optimized picking paths

This alone costs minutes per pick wave.

No Multi-Scan Support

Most old devices scan one barcode at a time.

Modern workflows require:

- Shelf scanning

- Batch picking

- Pallet scanning

- Multi-label verification

barKoder-enabled smartphones/tablets can scan dozens of barcodes in a single frame.

Slow Chips + Outdated OS

Many scanners run:

- Android 4/5/6

- Slow processors

- Tiny RAM

They can't run advanced software or get modern security patches.

Limited Update Support

Old devices stop receiving updates after:

- 3–4 years of release

Leaving them:

- Vulnerable

- Incompatible

- Hard to integrate

- Impossible to secure

In 2026, that’s a dealbreaker.

Real-World Cost Example: 50 Scanners in a Mid-Sized Warehouse

Let’s do the math.

A typical warehouse uses 50 industrial handhelds.

Initial Costs:

50 × €1,200 = €60,000

Accessories: +€15,000

Total: €75,000

Annual Ongoing Costs:

- Repairs: €8,000–€12,000

- Batteries: €4,000–€6,000

- Licenses/support: €3,000–€7,000

- Downtime loss: €20,000–€40,000

Total Annual Cost:

€35,000–€65,000 per year

5-Year Cost:

€175,000–€325,000

This is why warehouses think scanners “cost nothing” — because these costs hide across departments, invoices, and time.

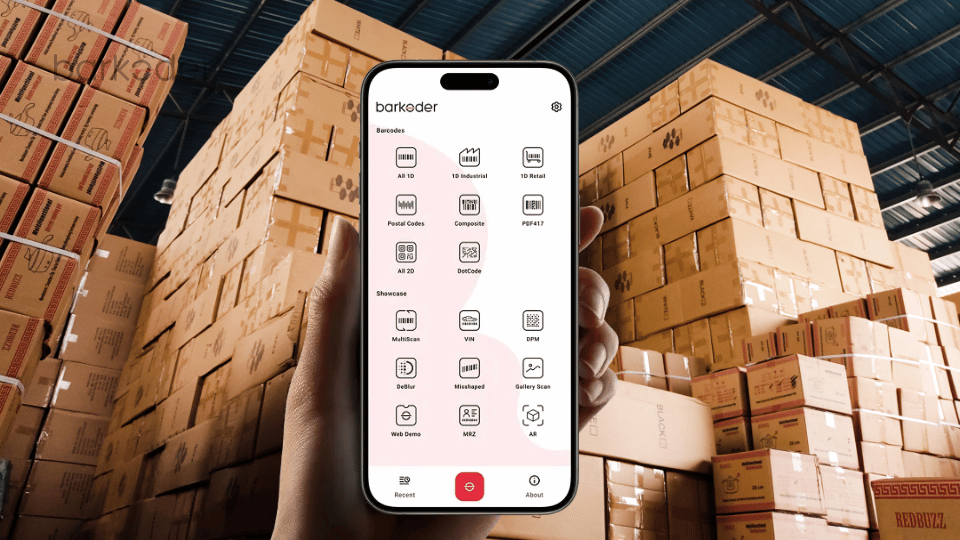

Compare That With BYOD + barKoder

Now imagine:

- Workers use the devices they already have (BYOD).

- Or the company buys €150–€300 Android phones.

- You install barKoder SDK and instantly have industrial-grade scanning.

- Multi-scan.

- AR support.

- Fast AI-enhanced decoding.

- Daily app updates.

- No proprietary hardware, no repairs, no charging cradles.

Cost for 50 users:

Phones: €9,000–€12,000

barKoder licenses: a fraction of hardware costs

No accessories

No repairs

Zero downtime for hardware

Instant replacements

Instant updates

Annual savings:

€40,000–€80,000 per year

(proven in dozens of real warehouses)

The Old Scanner ROI Myth Is Dead

For years, managers trusted old handheld scanners because they “just worked.”

But in 2026, the real question is:

At what cost?

The hidden expenses, inefficiencies, and limitations quietly drain tens of thousands of euros every year.

Modern warehouses don’t compete with labor — they compete with time, accuracy, and data.

And in that world:

- Slow devices lose money

- Heavy devices slow workers

- Outdated devices break workflows

- “Durable” devices become expensive anchors

Smart managers already know the truth:

Switching to mobile scanning isn’t a risk — it’s a financial upgrade.

And with powerful scanning platforms like barKoder, a smartphone becomes:

- Faster

- Cheaper

- Smarter

- Easier to update

- Easier to replace

- Better for workers

- Better for managers

- Better for the entire operation

The warehouses that win in 2026 won’t be the ones with the toughest scanners.

They’ll be the ones with the smartest ones.