Barcode Scanning in Military Submarines: Silent Precision Beneath the Surface

Deep beneath the ocean’s surface, military submarines operate in one of the most demanding environments on Earth. Every system must function flawlessly, every process must be traceable, and every decision must be based on accurate data. In this context, barcode scanning—often overlooked—plays a critical role in logistics, maintenance, and operational readiness aboard submarines.

Inside a submarine, space is measured in centimeters, not meters. Thousands of components—from replacement valves and electronic modules to medical supplies and emergency equipment—must be stored with absolute precision. A misplaced or untracked part is not just an inconvenience; it can delay repairs, compromise safety, or even jeopardize a mission. Barcode scanning transforms this complexity into order, allowing crews to instantly identify, locate, and verify critical items even under high pressure.

Unlike surface operations, submarines cannot rely on constant connectivity. Systems must work offline, silently, and securely. Barcode scanners aboard submarines are therefore designed to function without cloud access, syncing data only when secure connections become available. This ensures that inventory records, maintenance logs, and equipment histories remain accurate throughout long deployments beneath the sea.

Maintenance is where barcode scanning truly becomes a silent guardian. Every component on a submarine has a service life, inspection schedule, and compliance requirement. By scanning barcodes during inspections or part replacements, crews create an unbroken digital trail—recording who performed the task, when it was done, and which component was used. This level of traceability supports preventive maintenance, reduces human error, and helps commanders make informed decisions about system readiness.

The submarine environment also pushes technology to its limits. Low light, vibration, confined spaces, and protective gear can make manual data entry impractical. Barcode scanning offers speed and reliability where keyboards and paperwork fail. A single scan can replace multiple steps, saving time during critical operations and reducing cognitive load on crew members.

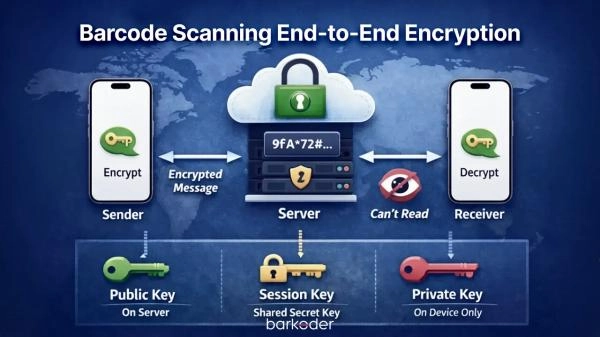

Security adds another layer to the story. Submarine logistics data is highly sensitive. Modern barcode systems are integrated with encrypted software platforms and access controls, ensuring that only authorized personnel can scan, view, or modify information. In this way, barcode scanning supports not just efficiency, but also operational secrecy and national security.

As naval fleets modernize, barcode scanning is increasingly paired with mobile devices, rugged tablets, and specialized SDKs that integrate directly into onboard systems. These tools turn raw scan data into actionable intelligence—highlighting usage patterns, predicting part failures, and supporting mission planning long before issues arise.

In the silent world beneath the waves, barcode scanning rarely draws attention. Yet scan by scan, it helps submarines remain mission-ready, safe, and efficient. It is a reminder that even in the most advanced military technology, reliability often depends on simple ideas executed flawlessly—proof that sometimes, the smallest tools carry the greatest responsibility.

Why Barcode Scanning Matters in Submarine Operations

Military submarines are complex, self-contained ecosystems. Space is limited, missions are long, and resupply opportunities are rare. Barcode scanning enables precise tracking of thousands of components, consumables, and critical assets, ensuring that crews know exactly what is onboard at all times.

Every item aboard a submarine—from spare mechanical parts and electronic modules to food supplies and medical kits—must be carefully accounted for before deployment and continuously monitored throughout the mission. Barcode-based inventory systems eliminate guesswork by providing real-time visibility into stock levels, usage rates, and remaining reserves. This allows crews to plan consumption intelligently and avoid both shortages and unnecessary overstocking in an already space-constrained environment.

During extended underwater operations, even small inefficiencies can compound into serious risks. Barcode scanning helps prevent this by streamlining inventory checks and reducing manual logging, which is time-consuming and prone to human error. A quick scan confirms item identity, quantity, and storage location, allowing crew members to focus on operational tasks rather than administrative work.

Barcode tracking also supports mission planning and readiness. By analyzing scanned data from previous deployments, commanders can better predict which parts and supplies are most critical for future missions. This data-driven approach improves loadout decisions, reduces waste, and enhances overall operational efficiency.

In emergency scenarios, accuracy becomes vital. When time is limited and conditions are stressful, barcode scanning allows crews to locate critical equipment or replacement parts instantly. The confidence that every asset is accounted for contributes directly to safety, reliability, and mission success.

In a world where submarines must operate independently for weeks or months at a time, barcode scanning acts as a quiet but essential system—maintaining order, visibility, and control deep beneath the surface, where precision is not optional, but essential.

Key objectives include:

- Accurate inventory management in confined spaces

- Traceability of spare parts and critical systems

- Maintenance history tracking for safety‑critical equipment

- Reduced human error during high‑stress operations

In an environment where mistakes can compromise mission success—or lives—reliable data capture is essential.

Extreme Conditions Require Reliable Scanning

Submarines present unique challenges for scanning technology:

- Low or inconsistent lighting

- Vibration and constant motion

- Humidity and temperature variations

- Strict electromagnetic and security constraints

Modern barcode scanning solutions, especially software-based scanning SDKs running on rugged mobile devices, are designed to operate reliably under these extreme conditions. Advanced decoding algorithms can read damaged, low-contrast, or partially obscured 1D and 2D barcodes, even when visibility is limited by low light, condensation, or tight physical spaces.

Unlike traditional scanners, mobile SDKs leverage powerful onboard cameras and real-time image processing to adapt automatically to changing environments. They can compensate for motion, vibration, and uneven lighting—common realities inside a submarine—while maintaining fast and accurate scan performance. This flexibility allows crew members to scan components quickly without needing perfect alignment or ideal conditions.

Equally important, software-based scanners can be tightly integrated into secure onboard systems. Scan data is processed locally on the device, reducing reliance on external connectivity and supporting strict security requirements. When synchronization is required, data can be transferred in controlled, encrypted sessions, preserving both operational integrity and confidentiality.

As submarines continue to modernize, these intelligent, mobile scanning solutions are becoming a natural fit—combining durability, adaptability, and precision in environments where technology must perform flawlessly, every time.

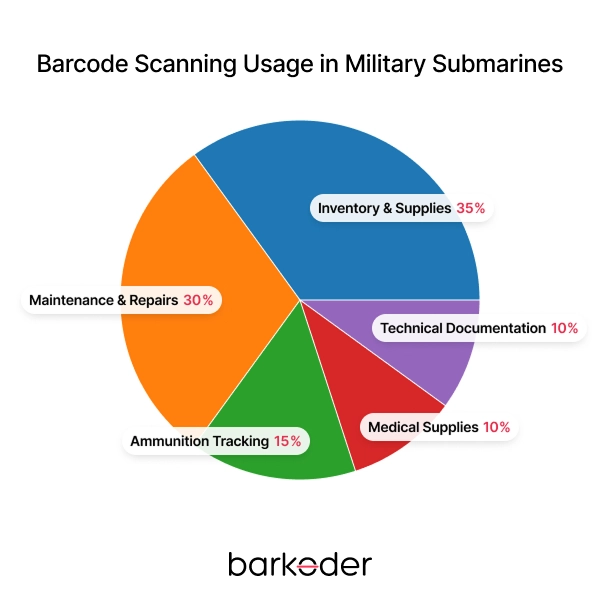

Use Cases Aboard Military Submarines

Inventory and Supply Chain Control

Every mission depends on precise control of supplies—from food and medical kits to mechanical and electronic components. In a submarine environment, where resupply is impossible and margins for error are extremely small, even minor inventory mistakes can have serious consequences. Barcode scanning provides the accuracy and visibility needed to manage these resources with confidence.

By integrating barcode scanning into daily operations, crew members are able to:

- Track inventory consumption in real time

- Prevent shortages of mission‑critical items

- Optimize storage and resupply planning

Maintenance and Lifecycle Management

Submarine systems require rigorous maintenance schedules to ensure reliability, safety, and long-term operational readiness. Every component—no matter how small—has defined inspection intervals, service procedures, and replacement cycles. Barcode scanning creates a direct link between physical components and their digital maintenance records, eliminating ambiguity and manual tracking.

By scanning parts during inspections and repairs, maintenance teams can:

- Verification of part authenticity

- Accurate logging of inspections and repairs

- Full lifecycle traceability for safety‑critical equipment

Ammunition and Sensitive Asset Tracking

Barcode scanning is also used to manage sensitive and regulated items, where accountability is not optional but mandatory. On a military submarine, this can include classified equipment, weapons-related components, specialized tools, medical supplies, and controlled materials that must be tracked with absolute precision. Secure, offline-capable scanning ensures that every movement of these items is recorded, even during extended deployments with no external connectivity.

Each scan creates a verifiable audit trail—who accessed the item, when it was issued or returned, and where it is stored. This level of traceability supports strict military protocols and reduces the risk of loss, misuse, or unauthorized access. Because scanning systems operate locally and offline, sensitive data never needs to leave the submarine until a secure synchronization window is available.

Modern barcode systems can also enforce role-based access, allowing only authorized personnel to scan or interact with specific categories of assets. This adds an additional layer of operational security while simplifying compliance with internal regulations and international standards.

In high-stakes environments where documentation errors can have serious consequences, barcode scanning replaces manual logs with consistent, tamper-resistant digital records. The result is greater control, stronger accountability, and confidence that critical assets are managed correctly—quietly supporting mission integrity deep beneath the surface.

Market and Technology Context

While military applications are often undisclosed, defense logistics represents a significant share of high‑reliability scanning deployments. Globally, the barcode scanning market was valued at USD ~2.4–2.9 billion in 2024–2025, with steady growth driven by automation, traceability, and mission‑critical operations.

Key trends relevant to military and naval environments include:

- Growing adoption of 2D barcodes (QR Code, Data Matrix) for higher data density and error correction

- Increased reliance on mobile scanning SDKs instead of dedicated hardware

- Expansion of offline and edge processing for secure environments

Defense organizations increasingly favor software‑defined scanning solutions that can be customized, audited, and integrated into secure systems.

Mobile Barcode Scanner SDKs in Submarine Environments

Modern barcode scanner SDKs enable submarines to use secure, ruggedized tablets or handheld devices rather than single-purpose scanners. This shift offers greater flexibility while maintaining the reliability required for mission-critical operations. Instead of carrying multiple dedicated tools, crew members can rely on a single, hardened device that supports scanning, data entry, and system access in one secure platform.

These software-based solutions are designed to run entirely on-device, ensuring fast response times and continued operation without network access. Updates, configurations, and custom workflows can be managed centrally when secure connections are available, reducing maintenance overhead and extending device lifecycles.

Benefits include:

- Reduced hardware footprint

- Easier updates and long‑term software support

- Custom workflows tailored to naval procedures

- On‑device processing without network dependency

SDK‑based scanning aligns with the broader shift toward modular, software‑centric defense systems.

Security and Reliability First

In military submarines, data security is non-negotiable. Barcode scanning systems must support strict security requirements while remaining simple and reliable for daily use in high-pressure environments. Every scan represents sensitive operational data, and protecting that data is as critical as capturing it accurately.

To meet these demands, barcode scanning systems must support:

- Offline operation

- Secure data storage

- Controlled access and auditing

- Long lifecycle support

Modern scanning SDKs are designed with these requirements in mind, ensuring that operational integrity is never compromised.

The Future of Barcode Scanning Below the Surface

As naval operations become increasingly data‑driven, barcode scanning will continue to evolve from a logistical tool into a strategic capability. Combined with analytics, predictive maintenance, and intelligent software platforms, scanning technology supports readiness, efficiency, and mission success.

In the silent world beneath the waves, every scanned code tells a story—of preparedness, precision, and trust. Barcode scanning may be invisible to the outside world, but within a military submarine, it is a quiet force that keeps operations running smoothly.